Who we are

Founded in 2021, Barmeter was created to solve one of the biggest challenges in construction: the gap between engineering intent and fabrication reality. We exist to make structural steel truly buildable delivering detailing and engineering that converts complex design requirements into clear, constructible solutions. Our long-term vision is to transform Barmeter into the central intelligence platform for the steel industry, where detailing, engineering, fabrication, and field coordination operate on a single connected system. We are committed to a future where every project runs with zero rework, complete clarity, and full traceability from concept to erection.

Barmeter is backed by leaders with over 20 years of experience in structural steel detailing and engineering, supported by postgraduate professionals who bring C-level strategic vision and technical depth. Our connection engineering is performed by licensed partners covering 80% of the U.S., ensuring Barmeter can support complex steel projects almost anywhere in the country.

Our Detailing & Engineering DNA

-

Quality

We convert complex engineering & architectural intent into precise, fabrication-ready solutions that eliminate ambiguity, reduce RFIs, and ensure every detail is constructible in the real world.

-

Zero Rework Philosophy

Every model, connection, and drawing is produced with a zero rework mindset, backed by rigorous QC and engineering validation designed to save time, cost, and field effort.

-

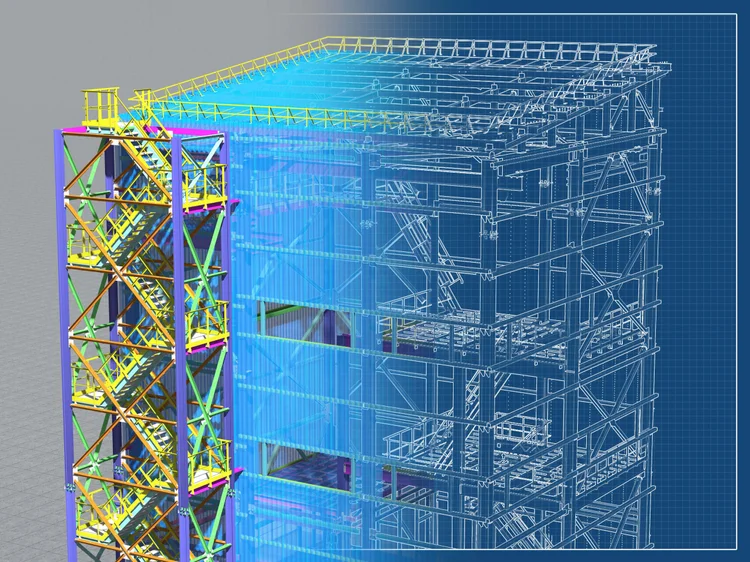

Technology Driven Efficiency

We leverage advanced tools, automation, and integrated workflows to deliver faster, cleaner, and more coordinated outputs empowering fabricators and GCs to make decisions with confidence.

Our Integrated Technology System

SDS/2 Training & Education Center

Our training programs equip students and professionals with real world SDS/2 and steel detailing skills through structured, project based learning.